You know that refreshing feeling after you deep clean and declutter your house? That’s what streamlining business and production processes can feel like (mop and trash bags not included). When you remove non-essential processes that add minimal to no value and focus on more important endeavors, you create a lean, efficient, and focused team.

The problem is that many businesses put the cart before the horse. They build robust product roadmaps, recruit top talent, and improve workplace culture to remain competitive. However, these goals are incredibly challenging if leaders haven’t already prioritized monitoring and improving their company’s operational efficiency.

What is Operational Efficiency?

Operational efficiency is the balance between an organization’s output and input, aiming to reduce costs and increase revenue by producing high-quality products with minimal resources.

Luckily, increasing operational efficiency isn’t one more thing to put on your plate. Instead, it’s an overarching company strategy that guides your other business decisions.

To do so, organizations make the most of their time, personnel, equipment, finances, and inventory in a cost-effective and productive way.

That can look like:

- Focusing on clear and consistent communication to reduce misunderstandings, improve collaboration, and build strong workplace relationships.

- Making operational efficiency a central tenet of company culture to establish best practices and expectations across teams.

- Strengthening external relationships with suppliers to reduce lead times and production costs.

It’s important to note that being operationally efficient doesn’t mean cutting headcount and resources just to reduce costs. Those choices can quickly lead to employee burnout, lower productivity, and increased turnover. Review your workforce capacity plans before making any personnel decisions to ensure employees reach their full potential without additional stress.

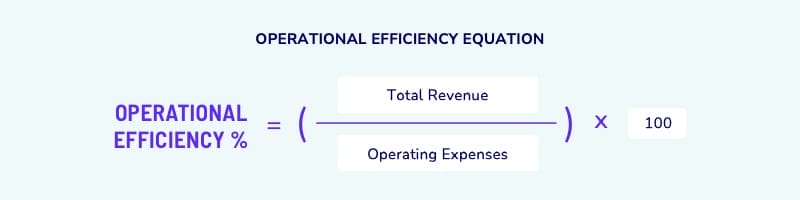

How to Calculate Operational Efficiency

To calculate operational efficiency, divide operating expenses by the total revenue and multiply the result by 100. This provides a percentage that indicates the company’s operational efficiency.

Measure your operational efficiency ratio as a part of your performance metrics to keep leaders accountable and aligned with business goals.

Why Increasing Operational Efficiency Matters

If you want to remain competitive, improve profitability, and adapt to changing market conditions (and let’s be honest – who doesn’t), you need to focus on increasing operational efficiency.

By optimizing processes, you’ll inherently minimize waste and maximize productivity, which can lead to:

- Innovation and continuous improvement, resulting from analyzing processes and identifying areas of improvement.

- Scalability, since efficient operations provide a solid foundation for growth.

- Customer loyalty and repeat business because shorter wait times, faster response to inquiries, and consistent product quality result in better customer satisfaction.

4 Ways to Improve Operational Efficiency

Operational efficiency isn’t just about putting the right tools in place, nor is it achieved with a few piecemeal efforts here and there.

Operational efficiency is even more than a set of practical steps and applications. It’s a philosophy and a mindset that has to permeate your company at every level — from employees to managers to leadership.

While the following four suggestions aren’t the only ways to improve processes, they’re solid strategies to create a systemic approach to increase operational efficiency.

1. Use Capacity Planning

Picture this: You’re running a business, and things are going great. You’ve got orders coming in left, right, and center. But suddenly, you hit a snag. Your production line can’t keep up with the demand, or your servers start crashing because too many users are flooding your website. It’s a nightmare scenario, right?

That’s where workforce capacity planning comes in. By analyzing past data, market trends, and other factors, you can figure out exactly how much capacity – in terms of production, infrastructure, or resources – you will need to meet future demand.

Additionally, you’ll better understand when to hire, spread the workload, or boost output to meet specific goals. A more realistic and granular understanding of your workforce capacity plans helps you ensure your next steps are operationally efficient and sustainable.

2. Prioritize Information-Sharing and Collaboration

McKinsey reports that two-thirds of goals fall short or are unsustainable due to siloed teams and information. Moreover, organizations with information-sharing strategies outperform siloed teams by 30-40%.

These are huge disparities – and ones that you can mitigate by prioritizing collaboration as a step to improve operational efficiency.

Beyond boosting employee productivity and reducing bottlenecks, focusing on information-sharing also leads to:

- Increasing engagement

- Enhancing resiliency to volatility

- Strengthening the employee experience

- Fostering DEIB efforts

Make it a priority to analyze collaborative processes and identify areas for improvement. This culture of continuous improvement will encourage innovation within your organization, leading to the development of new products, services, or operations that can further enhance competitiveness and profitability.

3. Implement Automation and Technology

Instead of relying on old ways of working (i.e., manual effort, paperwork, and substantial administrative overhead), many companies have adopted a more modern approach: using technology in almost every aspect of the business. That’s because software and AI tools streamline business processes, cut costs, and produce better products and services.

To be honest, this isn’t groundbreaking information. We’ve seen the effects of automation over the last few years and the (mostly) positive results.

But there’s a growing challenge emerging, according to business author Jeff Gothelf. As teams begin mastering “these new ways of working — improving time to market, continuous learning, responsiveness, and collaboration — they often find that the pace of work they desire is substantially hindered by the lack of agility in HR.”

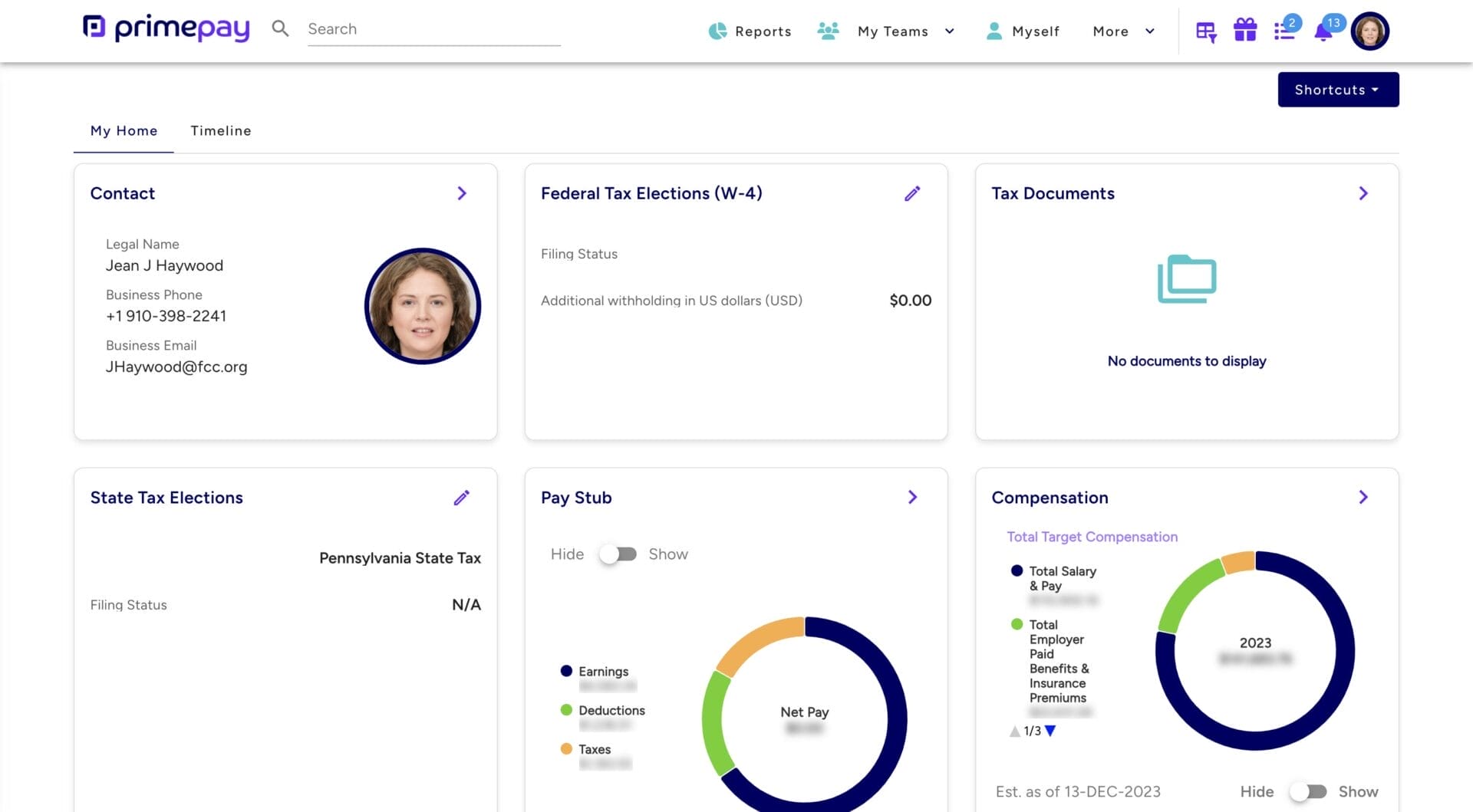

It’s therefore increasingly important to equip your HR team with the right technology so they can better respond to ongoing changes in the company and the working world. Consider investing in software that provides HR with the information they need and allows employees to access their own data to reduce back-and-forth communications.

With an employee self-service portal, employees can view their benefits, pay, tax documents, and more without emailing HR.

4. Focus on Employee Engagement and Training

When operational efficiency is an integral part of your company culture, every effort aligns to reduce waste and increase profit, and, by extension, can make your company a more dynamic, adaptable, and enjoyable workplace.

To get that “all in” feeling, focus on employee engagement and training at all levels. Consider regularly promoting best practices, prioritizing employee well-being through incentives and programs, and embedding career mapping in your performance management.

Ultimately, when organizations design and implement a positive employee experience, they’re 2.4 times more likely to be high-performing at workforce productivity, DEIB, and shaping a strong culture.

Improving Operational Efficiency for Future Success

Improving operational efficiency isn’t just about getting through the day-to-day grind – it’s about setting the stage for future success. By implementing technology, capacity planning, collaborative efforts, and employee training, organizations position themselves to adapt and thrive.

When operations run smoothly and efficiently, it frees up valuable time, energy, and resources that people can redirect toward innovation, expansion, and strategic initiatives. This agility and flexibility enable organizations to seize opportunities, weather challenges, and stay competitive. Efficiency isn’t just a short-term fix; it’s a long-term investment in sustainability and growth.